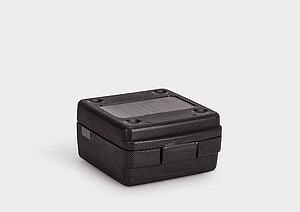

The patented shank clamping of the TopPack XPress guarantees the perfect clamping fit of the tool. At the same time, it enables simplified and convenient loading of the packaging. New: In addition to the previous 3 mm shank, there is now also a base plug for 2.0 mm shank clamping.

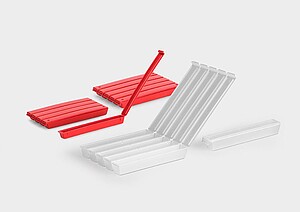

User convenience and optimal holding are paramount when packing shank tools. The diagonally positioned clamping ribs are only pressed firmly against the shaft after the transparent protective sleeve has been inserted and snapped into place. A further advantage: Sensitive cutting edges of milling tools remain protected all around without contact. At the same time, the risk of injury from sharp tool blades is reduced - both during the assembly process at the manufacturer's and during subsequent removal at the user's: if the protective sleeve is removed, the clamping in the plug is released again. The tool can easily be removed.

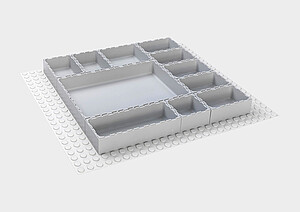

Colors, sizes, materials

The outer part of the TopPack XPress is available in polypropylene (PP), the base in polyethylene (PE). The base plug and adapter are available in attractive standard colors, the outer part in transparent. The variety of sizes fits almost any needs. (sb)

Learn more about the TopPack XPress.